Standing open in everyday life, safely closed in case of a fire alarm!

A hold-open system allows the barrier-free access of fire protection closures by self-closing them in case of fire or smoke development. Therefor the hold-open system releases in case of smoke detection the hold-open device, so the door closes reliably.

A hold-open system consists at least of:

- a fire, smoke or (if neccessary) heat detector,

- a signal processing control unit ,

- a power supply unit connected to the mains,

- a hold-open device, which is connected to a power supply unit and

- a manual release switch/pushbutton

Further components of a hold-open system:

- a legally required optical and acoustic warning signal even during power failure

Example setup of a hold-open system

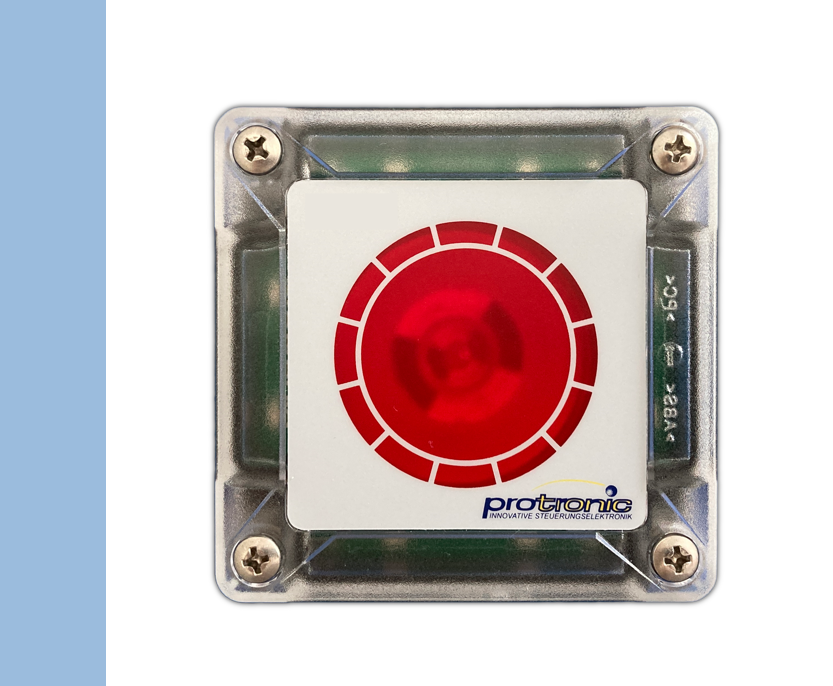

Hold-open system RZ-24-FA with warning signal WS-24-R

Hold-open systems, according to the “Guideline for the Authorisation of Fire Protection Closers” of the German Institute for Construction Technology (DIBt) in Berlin, have to be self-closing. In Germany, if there is the need to keep fire closures constantly open, an officially approved hold-open system must be used.

For further information or a quotation for your individual hold-open system, contact us:

Sales RZ-24

Andree Kölbel

vertrieb@protronic-gmbh.de

Tel.: +49 34383 6315-18

Training courses

authorization for acceptance tests and maintenance of hold-open systems

We offer training courses for:

specialist for hold open systems (acceptance test and maintenance)

Information and dates:

Internal sales

vertrieb@protronic-gmbh.de

phone: +49 34383 6315-18

Installation and maintenance of a hold-open system

Installation: After the professional installation, an acceptance test is required. The official acceptance test has to be arrangend by the facility operator and has to be performed by the manufacturer or a certified person (specialist for hold opensystems or acceptance test specialist).

Maintenance: The facility operator must guarantee the hold-open system operational constantly, and check the errorfree functioning once a month/every three monts. The facility operator is obligated to perform an annual inspection of the proper and failure-free interaction of the devices and general maintenance. The operator has to employ a qualified maintenance expert, or to commission a specialist company (certified specialist for hold open systems) to realise the maintenance of the hold-open system. The extent, result and date of the inspection and maintenance must be documented and archived.